plastic izod impact testing|izod impact test diagram : purchaser Notched Izod Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and . Resultado da Duas lésbicas estão no quarto na cama e se acariciam LGBT. Royalty Free Clips de Stock. DESCARREGAR. Adicionar à lightbox. Royalty Free. .

{plog:ftitle_list}

3. Link Theory to Practice In 1995, Nissan introduced, with the collaboration of Cranfield University, a workshop-based programme called Cogent, the immediate purpose of which is to improve first-tier suppliers’ ability to co .

Notched Izod Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and .Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018): Plastics — Determination of Izod pendulum impact resistance; ISO 180:2019: Plastics — Determination of .The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released. The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated from the height the arm swings to after hitting the sample. A notche.

ASTM D256 outlines the Izod impact test for plastics, emphasizing specimen preparation and machine calibration for accurate impact resistance data.

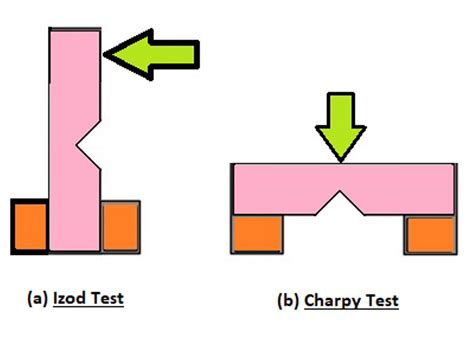

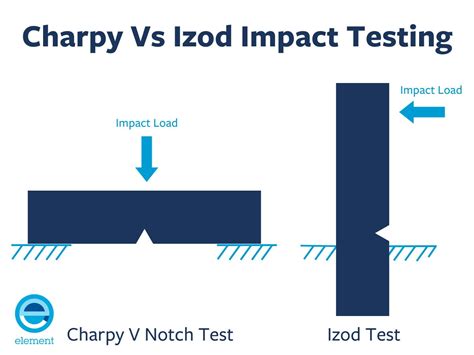

izod test vs charpy

Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180. The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. This singular point test offers a .Izod impact tests are commonly run at low temperatures - down to -40°F (-40°C) or occasionally lower - to help gauge the impact resistance of plastics used in cold environments.The ASTM D256 standard describes impact testing using the Izod test method for determination of the impact strength and notched impact strength of plastics. Izod impact tests are also described in standards ISO 180 and ASTM D4508.Abstract. 1.1 This document specifies a method for determining the Izod impact strength of plastics under defined conditions. A number of different types of specimen and test .

The Izod impact test is a widely used method for gauging the toughness and durability of plastic materials. This mechanical test precisely quantifies the energy absorbed by a material .Izod impact tests are used for characterization of the impact strength of a plastic or composite material at high strain rates. The flexural impact stress is applied to a notched or unnotched specimen gripped on one side, with .

Many industries use Izod impact testing for plastics. Nonetheless, this does not mean that Charpy impact testing for plastics is not possible. A Charpy impact test can be done to determine the ductility, toughness, and ductile-brittle . Discover the importance of the IZOD Impact Test in assessing the impact strength of materials. Learn about specimen preparation, plastic behavior, and ASTM D256 standards. . ISO 180 and ASTM D256 are important standards that show how to perform Izod impact tests on plastics with notches. They also give all the necessary steps and conditions .

The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials1.1 This document specifies a method for determining the Izod impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test parameters are specified according to the type of material, the type of test specimen and the type of notch.

Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.Impact tests on plastics – non-instrumented. There are ISO product, method, and instrument standards for impact tests with pendulum impact testers. . Other frequently used impact tests include the Izod test and impact tensile test. Izod tests, developed by ASTM, are widely used in the North American region, while Charpy tests are more .In accordance with to the ISO 180-2000 standard (ISO 180 2000), notched Izod impact tests are carried out.The impact behavior of polycarbonate specimens is analyzed. Rectangular plates of polycarbonate Lexan 141R, with dimensions 170 × 70 × 3.2 mm 3, are injection-molded.The melt temperature and the injection velocity are set to 295°C and 30 cm 3 /s respectively.

Discover impact testing methods like Charpy, Izod, and drop weight & learn how they ensure material safety, toughness, and reliability across industries. . It helps assess the impact resistance of plastic materials used in consumer products, automotive components, and packaging materials. Izod impact test standards. ASTM D256, ASTM D4508 .

TYPES OF PLASTICS IMPACT TESTERS • The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure. These test are typically pass/fail tests: TheyThe two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure. These test are typically pass/fail tests: They give the average impact energy required to break the samples. .Charpy Impact Test: Izod Impact Test: Material Types: All metals, plastics, and composites: Metals, plastics, and composites: Notch Types: U and V-shaped notch: Only V-shaped notch: Material Position: Horizontal: Vertical: Striking Point: Middle of material: The upper Tip of the material: Material Dimensions: 55 x 10 x 10mm: 64 x 12.7 x 3.2mm .

Izod Impact Test Home > Single Post Introduction to Izod Impact TestingIzod Impact Testing stands as a benchmark assessment to gauge the impact toughness of materials. By evaluating how much energy a material absorbs upon a sudden impact, this test illuminates the material's toughness—a crucial attribute for materials subjected to dynamic stresses in real .The robotic testing system roboTest H performs automated Charpy impact tests on plastics. The impact tests are performed at ambient temperature or on cooled specimens. . In an Izod impact test, the specimen is vertically gripped in the pendulum impact tester and the pendulum hammer breaks off the top part of the specimen.Izod Test Standards: Common Izod impact test methods include ASTM E23 & BS 131 for metals, and ISO 180 & ASTM D256 for plastics. Izod vs Charpy Test Comparison. One of the main differences from Charpy impact is that Izod .By testing plastics with the Charpy , IZOD test method the impact resistance of the plastic can be determined. Charpy and IZOD impact testing machine testercan also be used to determine the sensitivity of notched plastics specimens. Impact resistance of plastic notched specimens measures how will a cracked plastic specimen will withstand an impact.

This document specifies a method for determining the Izod impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. . Izod and tensile impact-testing; 3 Terms and definitions. For the purposes of this document, the following terms and definitions apply.

The Izod test is has become the standard testing procedure for comparing the impact resistances of plastics. While being the standard for plastics it is also used on other materials. The Izod test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in quality control applications .

Pendulum impact testers for plastics testing. By playing this video, you agree to the use of cookies as well as to the transfer of data to YouTube in the USA. Additional data privacy notices. . Izod impact test; Specimen range. Cooled specimens; Standards. ISO 179-1; ISO 180; ASTM D256; To the productOne of these variations is the ability to use either metallic or plastic specimens for the Izod impact test. The standard size of plastic samples is a bar with the following dimensions: 64 mm x 12.7 mm x 3.2 mm (V-shaped). Whereas metallic samples often come in the form of a circular, 11.42mm by 127mm bar with one to three machined V-shaped .Testlopedia - The Plastics Testing Encyclopedia; Izod Impact (Notched) ASTM D256, ISO 180; Multiaxial Impact (Dynatup Impact) ASTM D3763, ASTM D7192, ISO 6603, ISO 7765; Need help or have a question? +1 413 499 0983. Additional Phone Numbers. APAC +65 6805 4800. UK - Wilton +44 1642 435 788. Benelux +31 88 126 8888. Germany 0800 5855888.

testing rockwell hardness on receiver

testing rockwll hardness of foster bros knives

Izod Impact Test Understanding the Izod Impact Test: A Comprehensive Guide Introduction In the realm of materials testing, the Izod Impact Test stands out as a critical method for assessing the impact strength of plastics and other polymers. This test, integral to the offerings at Kiyo R&D Center & Laboratory, is a dynamic means to [.]The user attaches the appropriate striking tup on the pendulum and the specimen clamp or anvils in the base of the unit, to test plastics in accordance with ASTM D256 (Izod impact), ISO 179 (Charpy impact), ISO 180 (Izod impact), ASTM D6110 (Charpy Impact), ASTM D4812 (Unnotched Cantilever Beam Impact), ASTM D4508 (Chip Impact), ASTM D950 .

In the following will be presented the most common impact test on plastic material with the apparatus and the . 1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The .

The Izod / Charpy Impact Test represents a pivotal evaluation method in the material science industry, serving as a fundamental measure of a material's toughness and resistance to impact at varying temperatures. This testing methodology is critical for assessing the durability of plastics, metals, and ceramics under sudden stresses. Administered using .In the following will be presented the most common impact test on plastic material with the apparatus and the . 1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The .

INTERNATIONAL STANDARD ISO 180:2019(E) Plastics — Determination of Izod impact strength 1 Scope 1.1 This document specifies a method for determining the Izod impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined.

izod impact vs charpy

izod impact test diagram

40 2 39,7K. 57. 6. [deleted] Posta mais da Renata. Add a comment. LIVE SEX CAMS. Rhenata Schimit pictures and videos on EroMe. The album about Rhenata Schimit is to .

plastic izod impact testing|izod impact test diagram